Lead Acid Battery Transport Regulations

Lead Acid Battery Transport Regulations

Lead acid batteries must be transported in accordance with various federal & state regulations including dangerous goods, hazardous waste, road transport and workplace safety. The road transport requirements for New and Used Lead Acid Batteries are very similar except used lead acid batteries (ULAB) are also classified as a Hazardous Waste. Lead acid batteries are the most common type of batteries used in cars and other other motor vehicles.

If you are conducting a business or undertaking at a workplace whereby you are a consignor of either new or used lead acid batteries, then you need to ensure that when you or your subcontracted transport company transport lead acid batteries that you comply with these regulations.

Many companies are unaware of the “Chain of Responsibility” provisions which were adopted in October 2018, in the National Heavy Vehicle Regulations. The CoR provisions make it the responsibility of all parties, including consignors, in the transport chain to ensure compliance with regulations. All parties can be fined and held legally liable for breaches of the regulations. These provision have been adopted by all states except WA & the NT, which have implemented their own CoR requirements.

Below is a general guide which hopefully will fast track your research and understanding of the regulations that govern the safe and regulation compliant transportation of used lead acid batteries.

Follow this link, if you are more concerned with lead acid battery storage regulations.

Charges for Removal of Non Acceptable Batteries / Items

Our used battery collection and recycling service, delivers a safer, convenient service that meets your regulatory requirements, while reducing your environmental impact.

What Regulations Apply to the Transport of Lead Acid Batteries?

The key regulations that govern the transport of both new & used lead acid batteries, include;

The Australian Dangerous Goods Code (ADG Code), specifically the “Australian Code for the transportation of Dangerous Goods By Road and Rail”, sets out the requirements for transporting dangerous goods by road or rail. The code has been implemented in each State and Territory’s dangerous goods transport laws. The local transport laws provide important information such as supply chain member duties, including consignors, licensing requirements, penalties and competent authority panel powers. These regulations apply to both new and used or waste lead acid batteries.

Regulations for the transport of hazardous (controlled) waste within your state. These regulations only apply to waste or used lead acid batteries. Unfortunately there is no national regulatory model for the transportation of hazardous waste and consequently each state has it’s own set of regulations. While they have many similarities they are also different. The controlled waste regulations will usually be incorporated within your State’s environmental regulations. You can find further information at the bottom of this page, “Useful Links Regarding New & Used Lead Acid Battery Transport Regulations”, including requirements for interstate transport.

Heavy Vehicle National Law (HVNL), regulates heavy vehicles over 4.5 tonnes gross vehicle mass. The law has been regulated in Queensland, New South Wales, Australian Capital Territory, Victoria, Tasmania, and South Australia. The HVNL is underpinned by four regulations:

- Heavy Vehicle (General) National Regulation

- Heavy Vehicle (Fatigue Management) National Regulation

- Heavy Vehicle (Mass, Dimension and Loading) National Regulation

- Heavy Vehicle (Vehicle Standards) National Regulation

The HVNL was developed by the National Transport Commission and the resulting regulations are administered and serviced by the National Heavy Vehicle Regulator (NHVR).

Western Australia & the Northern Territory haven’t implemented the HVNL and have adopted their own heavy vehicle transport regulations.

The Load Restraint Guide 2018, provides the basic safety principles for the safe carriage of loads. If you’re involved in packing, loading, moving or unloading a vehicle, you are responsible for complying with load restraint laws. The Load Restraint Guide, developed by the National Transport Commission, outlines how you may meet the performance standards for restraining vehicle loads. The legal requirements are the performance standards referenced in the Heavy Vehicle National Law and are stated in Schedule 7 (pages 97–99) of the Heavy Vehicle (Mass, Dimension and Loading) National Regulation.

Note: Restraint requirements for WA & NT are contained in their own Road Traffic regulations, both of which reference the NTC’s Load Restraint Guide 2004.

What are the ADGC requirements for Transporting Lead Acid Batteries?

New requirements for the transportation of lead acid batteries (new & used) are to be adopted in edition 7.7 of the ADGC and became mandatory as of October 2021.

These changes apply to spillable or flooded lead acid batteries, which are classified as dangerous good, UN Number 2794, Proper Shipping Name “BATTERIES, WET, FILLED WITH ACID, electric storage”. The ADGC transport regulations for Non-spillable or sealed lead acid batteries are different as these batteries are classified as DG; UN Number 2800, “BATTERIES, WET, NON-SPILLABLE, electric storage”.

There have been significant changes made to the P801 Packing Instruction, which is shown below;.

You can download a printable copy of the new ADGC P801 Packing Instruction here. The previous P801 Packaging Requirements can be found at ADG Code’s P801 Packing Instruction.

The main change to the P801 is the inclusion of requirements for transporting used lead acid batteries (ULAB) in either stainless steel or plastic bins. These changes were introduced to remove the ambiguity as to whether the “additional requirements” in the current P801 Packing Instructions applied to ULABs being transported in bins.

The Australian Special Provision AU08, has also been modified in this edition. AU08 clarifies that it is the acid volume contained in the batteries that is used to define the aggregate quantity of dangerous goods (DG) in the load. If the acid volume is not known, usually the case for used batteries, a nominal figure of 25% of the gross weight of the batteries may be used.

Under the ADGC placard load requirements an aggregate quantity of 1000L of acid requires vehicle placarding. Using the 25% calculation, this means that quantities of more than 4000kg of used lead acid batteries would require DG placarding of the transport vehicle.

ADGC packaging requirements for a wood pallet

If you are using wood pallets, referred to as an overpack in the ADGC, then your packaged lead acid batteries should appear like the example below. It shows 30mm Cardboard being used to separate each layer (clause 1b) to prevent battery terminals damaging overlying batteries and the application of plastic wrapping and multiple straps to secure the load to the heavy-duty pallet.

When using a wood pallet, you packaged automotive batteries should appear like the example below;

ADGC packaging requirements for plastic bins / containers

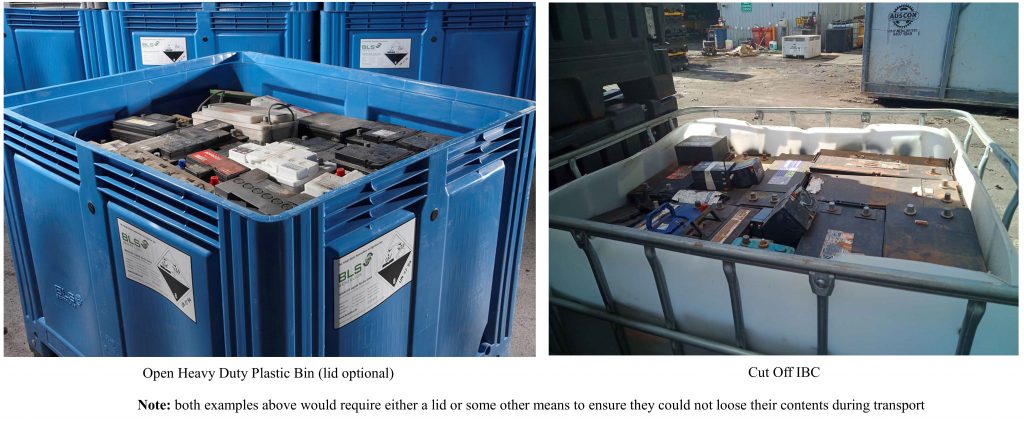

If you are using plastic bins or cut off IBC like those shown below, to transport ULAB then appropriate steps need to be taken to ensure that clauses 2b) and 2e) of the new P801 packing instruction are met. Also clause 2d) requires that no electrolyte shall leak from the bins. This can be an issue with cut off IBC which are prone to develop leaks, when heavy batteries are dropped into the IBC.

Battery Rescue’s BTS Container, pictured below, contains a permanently attached lid, so automatically meets the requirements of clause 2b) and 2e).

Clause 2f) states that “Measures shall be taken to prevent short circuits (e.g. batteries are discharged, individual protection of the battery terminals, etc.)”. As is usually the case the regulations don’t tell you how this should be done, although in this case they make a couple of suggestions, which don’t appear to be very practical.

For the majority of batteries, with plastic casing, the risk of short circuits can be eliminated by stacking each battery in a vertical, upright position, whereby the plastic bottom of the battery is resting on the terminals of the underlying battery. Provided the batteries are packed snugly the batteries will continue to remain in the upright position during transport and there will be no risk terminals touching each other and creating the conditions for a short circuit.

Steel case batteries and metal encased UPS’ require additional packing precautions as their metal cases can create a short circuit when resting on the terminals of an underlying battery. Our recommendation is that these batteries are stacked at the bottom of the Bin / Container so that they never make contact with other battery terminals or adequate insulation, such as a folded card board box, is placed between the underlying battery and the steel case battery.

What are the other ADGC Requirements

Labeling

- 2 Class 8 Corrosive Diamonds, minimum size of 100 x 100mm with minimum lettering size of 7mm, applied to opposite side of the package.

- All packages must be labeled with the UN Number 2794, proper shipping name “BATTERIES, WET, FILLED WITH ACID, electric storage”. Minimum 12mm lettering size.

- All packages must display the Name, address and contact number of the consignor. Minimum 12mm lettering size.

Note: It is an offence under the ADGC to transport an empty bin or container while displaying DG labels.

Load Restraint

- Packages (i.e. pallets, bins, IBC etc) must be stowed & restrained in the vehicle in accordance with the National Transport Commission’s Load Restraint Guide 2018 (for further details see “Useful Links“)

- In addition Chapter 9.2 of the ADGC requires that batteries being transported with incompatible dangerous goods or other goods, must be segregated. Note that when batteries are transported with other goods all goods must be restrained to prevent damage to the batteries and release of their electrolyte.

- If batteries are transported in an open or non-rigid sided vehicle (includes curtain sided vehicles), the battery packages must be;

- stowed & restrained within rigid sides or gates.

- no package or battery may protrude above the sides or gates by more than 30% of the height of the battery or package.

- no parts of a battery or package may protrude horizontally beyond the side gates.

- For further details read Chapter 8.1 of the ADGC.

Dangerous Good Transport Documentation

- The Consignor who provides the ULAB for transport shall provide the transport contractor information applicable to those dangerous goods.

- The documentation must be carried in the vehicle in hard copy form

- The documentation must include the name and address of the consignor, consignee, including the consignor’s contact telephone number

- The documentation should include the following information

- UN Number – UN2794

- Proper Shipping Name – BATTERIES, WET, FILLED WITH ACID, electric storage

- DG Class – 8

- Description of Packages – i.e. Pallet, Bulk Bin, IBC

- The number of each type of package

- The aggregate quantity of battery acid. If unknown use nominal figure of 25% of gross weight of batteries (as per Australian Special Provision AU08)

You can download here an example of the DG Transport Document for transporting Wet, Lead Acid Batteries (UN2794).

Emergency Information

The vehicle used to transport the dangerous goods, must carry the DG documentation, described above, and emergency information, as follows ;

- If a placard load (more than 4000kg of batteries) the vehicle must be fitted with an Emergency Information Holder otherwise documentation can be kept in a prominent location in the the cabin.

- Emergency documentation should include an Initial Emergency Response Guide, an Emergency Procedure Guide for the dangerous good, an Emergency Procedure Guide in relation to a vehicle fire.

- See Chapter 11.2 – Emergence Information in ADGC for further details.

Vehicle Placarding

Placarding of the transport vehicle is only required if carrying a placardable load (more than 1000L of electrolyte ~4000kg of used lead acid batteries). Fixed/Rigid vehicles, the placarding required is a 250 x 250mm Corrosive diamond to be displayed at the front and rear of the vehicle. For placarding requirements when transporting batteries using a semi-trailer, see Figure 5.3.6 in the ADGC.

Wood Pallets versus Plastic Bins

Frankly at Battery Rescue we are not big fans of wood pallets for the transport of used batteries. The materials required and complexity to package used lead acid batteries on wood pallets results in wide spread non compliance of dangerous goods transport regulations.

Furthermore wood pallets cannot capture the battery acid, which contains relatively high levels of lead and other heavy metals, posing a threat to both the environment and human health.

For further details see our white paper

“Why the Wood Pallet should be banned for Used Lead Acid Battery Storage & Transport”.

Controlled Waste Requirements for Transporting Used Lead Acid Batteries

Used Lead Acid Batteries are classified as a Hazardous & Controlled Waste. Regulations governing the transport of hazardous waste have been enacted by each State or Territory as part of their Environmental regulations. You will need to review the regulations specific to you state, which you can find at “Useful Links Regarding New & Used Lead Acid Battery Transport Regulations”.

In general these regulations will require that you only use a transport company that has a controlled waste license for used lead acid batteries. The provisions of a waste carrier license typically includes requirements such as;

- Marking the vehicle with the appropriate controlled waste signage.

- Vehicle must carry the appropriate spill containment equipment.

- Have an emergency response plan for the Driver

- Use of suitable containers to prevent leakage of fluid and waste into the environment (doesn’t that rule out wood pallets for transporting batteries?)

What are common examples of non compliant used battery transportation?

The most common compliance breaches that we have identified are:

- Failing to adequately wrap and strap the batteries when using wood pallets.

- Failing to use a 30mm, non conductive separator between each layer of batteries, as required when using an over-pack such as wood pallets.

- ULAB container / over-pack not labelled as “Class 8 Corrosive”, with UN Number 2794 and the proper shipping name displayed “BATTERIES, WET, FILLED WITH ACID, electric storage”

- ULABs not packed adequately (e.g. loose batteries on a pallet or truck tray).

- Non-existent primary restraint of pallets onto the vehicle .

- Sides and gates not utilised for secondary restraint.

- Absence of transport documentation detailing quantity and type of dangerous goods.

- Placard load requirements ignored (the vehicle requires placarding for more than 4 tonnes of ULAB).

- Operators carting ULABs without the state / territory controlled waste licence.

Below are some examples on non-compliant waste / used lead acid battery transport

Please note that the information provided here is general in nature. Companies must do their own research to understand their legal obligations in each jurisdiction and to ensure that they are fully compliant with transportation regulations for new & used lead acid batteries.

Useful Links Regarding New & Used Lead Acid Battery Transport Regulations

- Century Batteries, Safety Data Handling Sheet for Lead Acid Batteries.

- Australian Code for the transportation of Dangerous Goods By Road and Rail – See Chapter 4.1.4 for a list of Packing Instructions including P801 for batteries, Chapter 5.2 for Marking & Labeling requirements for Packages, Chapter 5.3 Placarding and Marking of Transport Units and Part 8 for Stowage & Restraint requirements.

- Each State or Territories Environmental Protection Regulations stipulate requirements for transporting and disposing of controlled hazardous waste, such us used / waste lead acid batteries, and the waste holder’s obligations. You can find the link to your state or territories hazardous waste regulations.

- The interstate transportation of ULAB is governed by a national agreement, National Environmental Protection (Movement of Controlled Waste Between States And Territories) Measure, which is administered by State Environmental Authorities.

- The National Transport Commission‘s (NTC) “Heavy Vehicle National Law”, regulated by the National Heavy Vehicle Regulator.

- The Load Restraint Guide 2018, provides the basic safety principles for the safe carriage of loads. The guide, developed by the National Transport Commission, outlines how you may meet the performance standards for restraining vehicle loads. The legal requirements are the performance standards referenced in the Heavy Vehicle National Law and are stated in Schedule 7 (pages 97–99) of the Heavy Vehicle (Mass, Dimension and Loading) National Regulation.

- The Australian Battery Recycling Initiative (ABRI), is an industry body established to promote the collection, recycling and safe disposal of all batteries. ABRI has published several useful documents outlining the regulatory requirements and “best practice” recommendations for the storage, handling and transportation of ULAB.