Battery Rescue was founded in 2014, by its sister company Uniseg Products, to demonstrate a safer more environmentally sustainable system for collecting used lead acid batteries (ULAB) for recycling. The Battery Rescue system revolved around the use of Uniseg’s Battery Transport & Storage (BTS) Container.

The decision to establish Battery Rescue was taken following the disappointing level of interest in the BTS Container by the lead acid battery recycling industry, when the BTS was originally launched. The industry seemed content to continue to use the wood pallets for the storage and transport of used lead acid batteries (ULAB), despite their many short comings and widespread non-compliance with various Dangerous Goods and Environmental laws.

Since then, Battery Rescue has continued to grow every year acquiring new customers wanting to manage their batteries in a safer more environmentally responsible way, while ensuring their compliance with relevant regulations.

Battery Rescue’s system was designed so that the BTS Containers would be delivered directly to the recyclers for automatic unloading, thus eliminating any manual handling of the batteries from the customer through to the recycler. Once unloaded the containers would be washed and returned for redeployment to our customers.

For many years we were unable to find an Australian lead recycler willing to accept batteries delivered directly in our BTS Containers and were required to manually unload the batteries from the Containers on to wood pallets for transport to the recyclers. This changed in 2022, with the commissioning of Western Australia’s first lead acid battery recycling plant, by Nexus Recycling. After a successful trial in July 2022, of the auto unloading, we have continued to deliver our BTS Containers to Nexus.

In the interim Uniseg Products has continued to sell BTS Containers, in Australia and overseas, however sales have been limited primarily to businesses who wanted a safer more convenient way to store their batteries. Most of our customers are having the batteries manually unloaded by a contractor for disposal from their site and hence are not benefiting from the safer, regulation compliant transport of their batteries.

The Scrap Metal Companies, which currently service the collection and transport of the ULABs to the recyclers, have until now been unwilling to offer the BTS Containers to their customers, despite the demonstrated success of Battery Rescue.

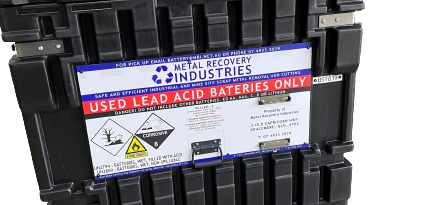

It appears that perhaps the penny has finally dropped for one Australian Scrap Metal company, Metal Recovery Industries. MRI, located in Central Queensland. MRI have recently purchased 40 BTS Containers and anticipate future purchases as it rolls out the BTS Containers to its customer bases.

Hopefully this is the start of widespread adoption of the BTS Container by the battery recycling industry.